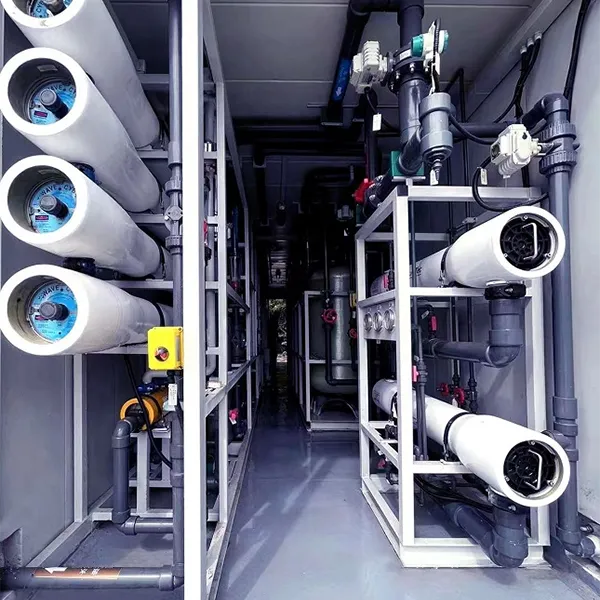

Drinking Water Defluoridation Systerm

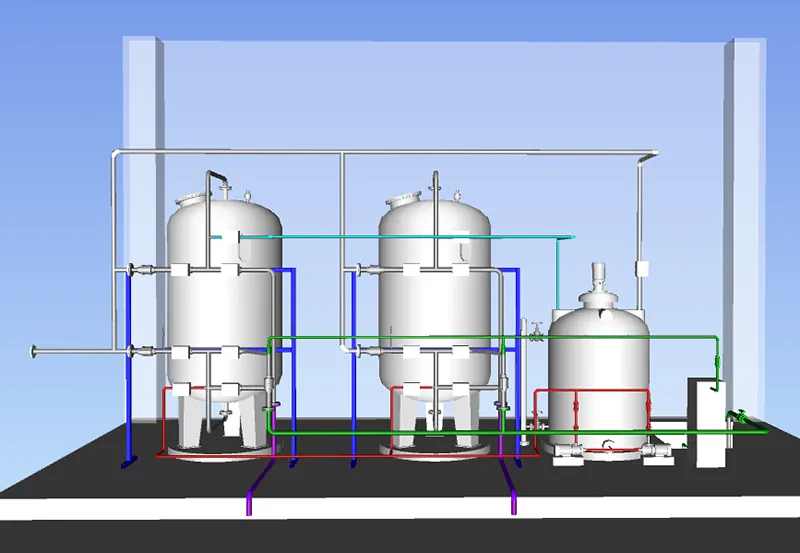

Working Principle:

When raw water passes through the defluoridation filter, it comes into contact with the internal core filtration layer. Through physicochemical reactions (adsorption), fluoride is adsorbed on the surface of the adsorbent, forming insoluble fluorides, which brings the fluoride content in water to the corresponding treatment standard. When the defluoridation capacity reaches a certain limit (saturation), the adsorbent is regenerated through regenerant, restoring its defluoridation capacity.

Operation Process

Fluoride-containing water passes through an adsorption filter layer with a large specific surface area. Under pH conditions of 5-6, fluoride ions in the water are adsorbed and converted into insoluble fluorides, thus being removed. After saturation, the adsorbent is regenerated using regenerating agents to restore its adsorption capacity. The ratio of regenerant dosage to defluorination capacity is 60:1. The regeneration concentration is 1%-2%. Every 3-4 months, clean the system with a 3.5% HCL solution. After cleaning, rinse with defluorinated water for 8-10 minutes. When the raw water pH is greater than 7, carbon dioxide gas is generally used for adjustment.

Technical Features

- Low cost and investment savings

- Small equipment footprint

- High water utilization rate, with water production efficiency over 98%

- Low operating costs and water production costs

- Simple equipment operation,automation or semi-automation

- Convenient installation and use, connect to frequency conversion pumps in deep wells, with direct water output to pipeline networks without additional pressurization

Get Free Quote of Drinking Water Defluoridation Systerm

Application Range

Suitable for industrial and mining enterprises, rural safe drinking water production (domestic) water treatment, and as pretreatment equipment for ultrafiltration, nanofiltration, reverse osmosis, ion exchange, mixed beds, EDI, etc. when raw water contains high levels of fluorine.